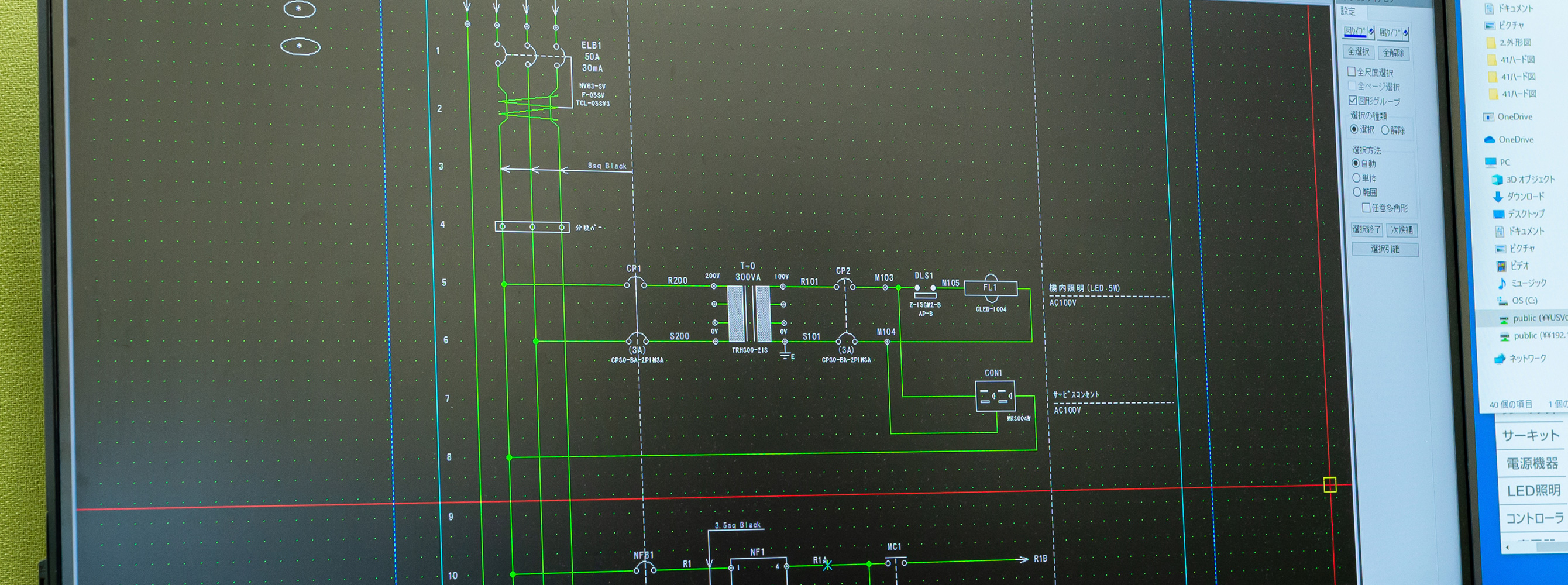

It is an electric design that can be said to be the factor in which the machine designed / manufactured in-house is important to achieve the operation at a client's request. Specialized electrical design staff are taking charge of it in a section separate from a machine design.

Depending on a time-chart and a flow chart from a machine designer,they are perfoeming the hard and soft design for controlling.

What the client needs is a facility which we cannot operate with only a machine. An electrical signal enters, and it is the 'facility' which can work one operation only after the control of the sequencer is accompanied.

We are always pursuing control of the higher enhanced model according to faithfulness in the demand of clients.

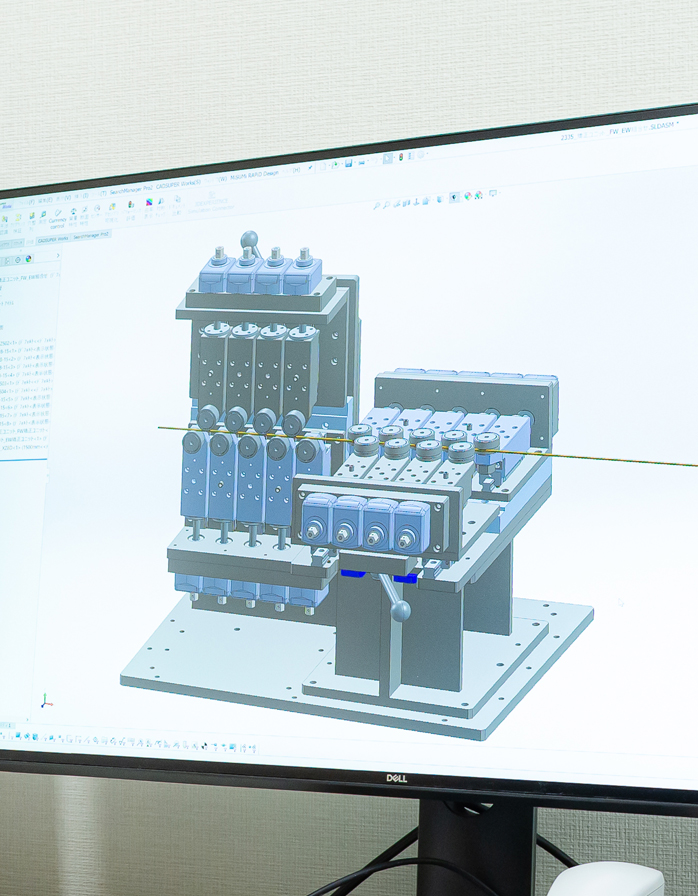

This is the section in charge of overall planning for each project,encompassing aspects such as systems, costs, and deadlines. Designers use moden CAD systems, and can formulate a range of plans in response to specific needs.

That's the important factor to actualize a requested mechanical movement. It performs electrical design in both hardware and soft both sides.

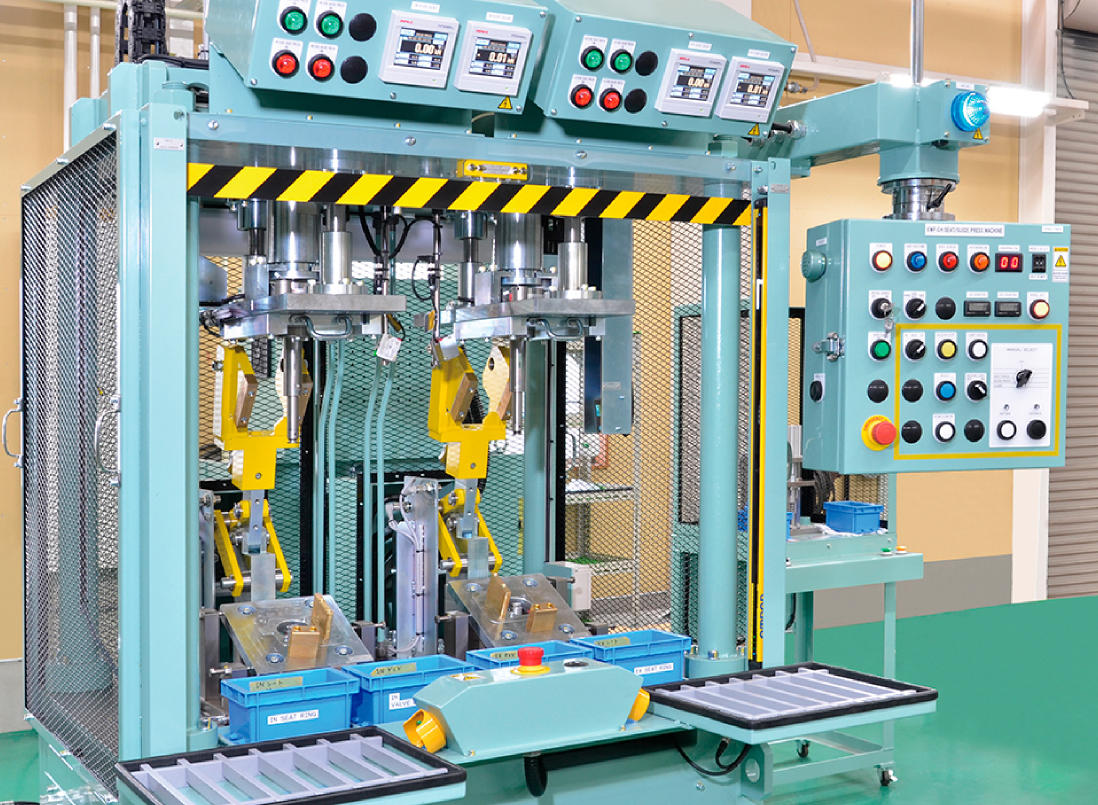

Because our company is founded on manufacturing creativity, the production of parts is a crucial function, directly affecting costs and delivery times for all the machinery we produce.

With safety and quality foremost in their minds, our assemblers carefully follow a predetermined process under the supervision of an experienced operations manager.