This section's work goes beyond mere design. The wealth of know-how accumulated within our company is brought together in technical review meetings for product development, where original client specifications are examined and proposals formulated for enhanced concepts and designs.

When planning new projects: Firstly, we seek optimum practicality in all devices and machinery. Secondly, we obtain a solid understanding of user needs in terms of cost, deadlines and so on, and aim for smooth implementation of each stage in the production process. Finally, we keep in mind that both the makers and the users of our products are real human beings, and that it's crucial to develop strategies to maximize the contribution of both sides in ensuring that client expectations are met.

These efforts must further be informed by a mindset of constant improvement in technical expertise. The ultimate aim of the System Design Section is to expand the frontiers of production and technology in our company.

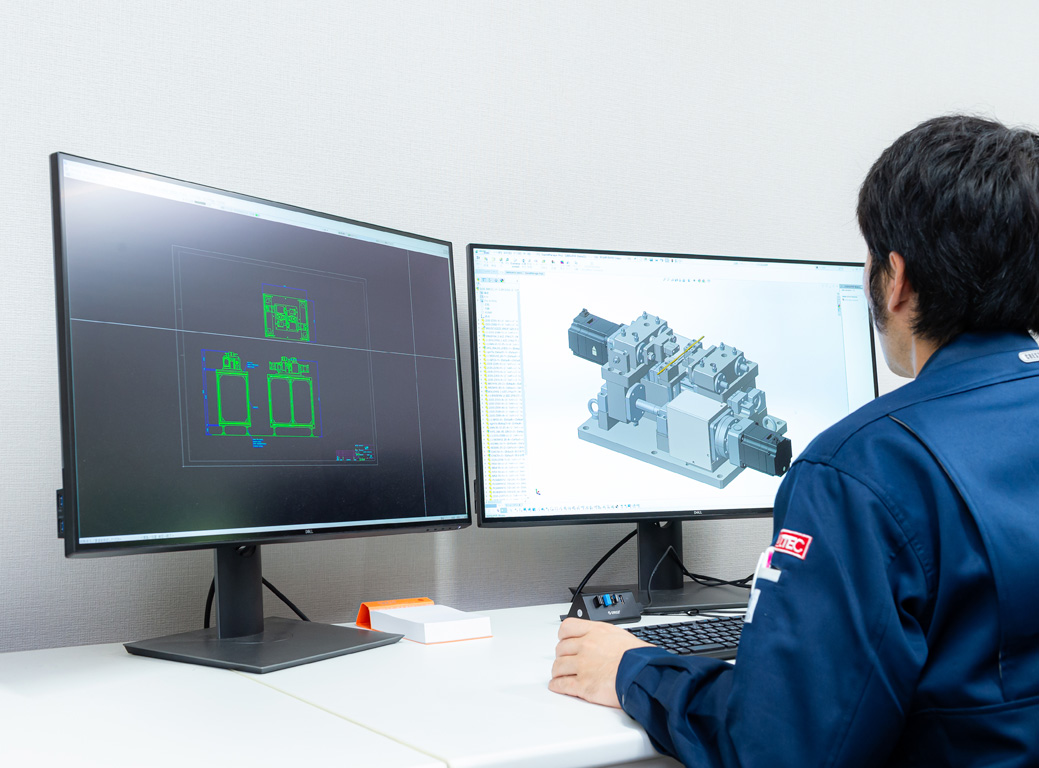

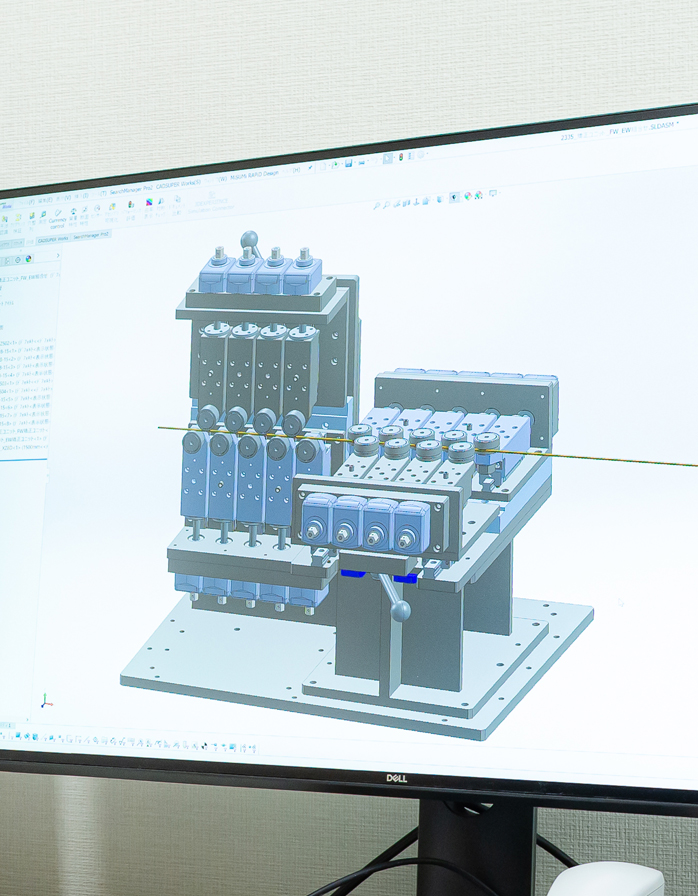

This is the section in charge of overall planning for each project,encompassing aspects such as systems, costs, and deadlines. Designers use moden CAD systems, and can formulate a range of plans in response to specific needs.

That's the important factor to actualize a requested mechanical movement. It performs electrical design in both hardware and soft both sides.

Because our company is founded on manufacturing creativity, the production of parts is a crucial function, directly affecting costs and delivery times for all the machinery we produce.

With safety and quality foremost in their minds, our assemblers carefully follow a predetermined process under the supervision of an experienced operations manager.