FA (Factory Automation)

A system that automates production and inspection lines in factories.

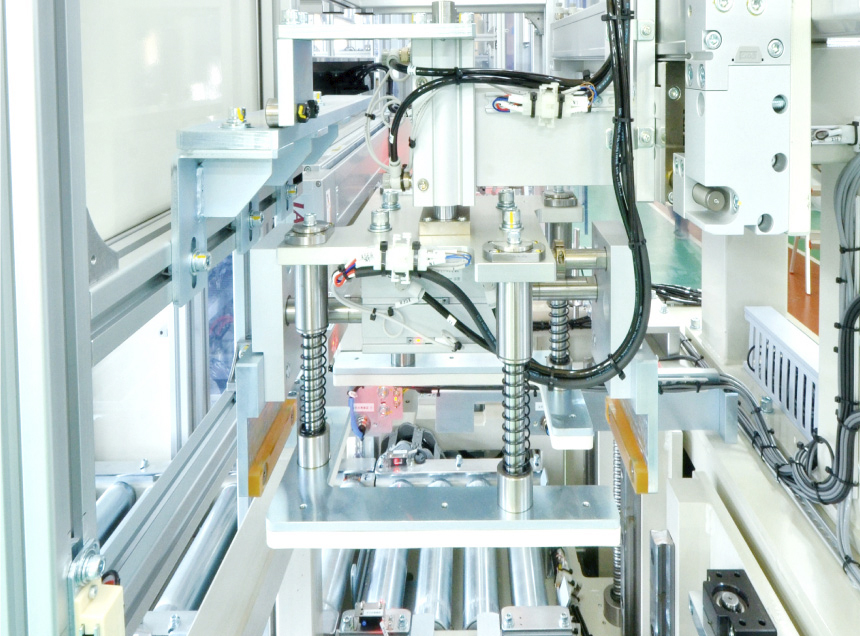

At U.TEC, we design and manufacture automatic machines, inspection machines, press-fitting machines, transfer machines, assembly machines, measuring instruments, etc., as FA equipment that realizes these, according to the customer's request.

The introduction of FA equipment is expected to significantly improve productivity because it can process various processes at speeds that exceed human work speeds.

In addition to cost reduction, it is also expected to improve inspection accuracy.This will contribute to yield improvement by reducing the percentage of defective products.As the global trend toward the DX era progresses, U.TEC will continue to play an active role as a "jack-of-all-trades" for our customers by using these FA devices.U.TEC will be your "anything and everything shop" by using these FA equipments.

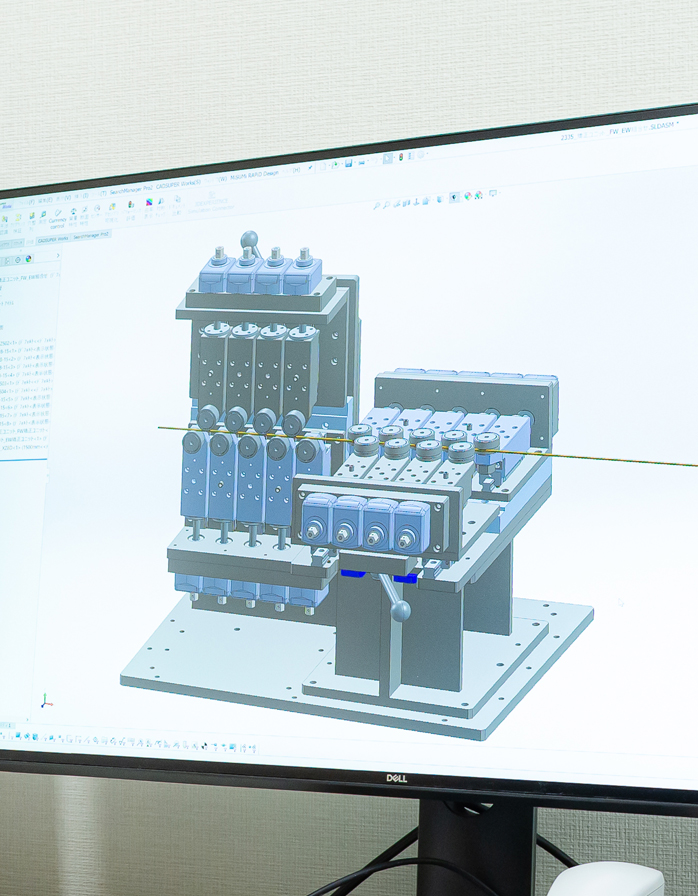

As part of U.TEC structure required to solve customers' problems, the system design, electric design, parts production, assembly, and inspection departments work together to promote projects.

This is the section in charge of overall planning for each project,encompassing aspects such as systems, costs, and deadlines. Designers use moden CAD systems, and can formulate a range of plans in response to specific needs.

That's the important factor to actualize a requested mechanical movement. It performs electrical design in both hardware and soft both sides.

Because our company is founded on manufacturing creativity, the production of parts is a crucial function, directly affecting costs and delivery times for all the machinery we produce.

With safety and quality foremost in their minds, our assemblers carefully follow a predetermined process under the supervision of an experienced operations manager.

From the time we receive an order right through the production process, our primary concern is to keep quality, cost and schedule in line with the client's demands.

This involves gaining a firm grasp of the kind of expertise the project requires, right from the initial ordering and consultation phase. Each subsequent stage in the production process is then approached in a methodical and precise manner.

These techniques have been developed to ensure that our work is just what the client ordered.

Our approach is simple, but it's sure to keep our clients satisfied.

Testing Machines

Testing Machines Testing Machines

Testing Machines Automated Assemble Machines

Automated Assemble Machines Press Fitting Machines

Press Fitting Machines